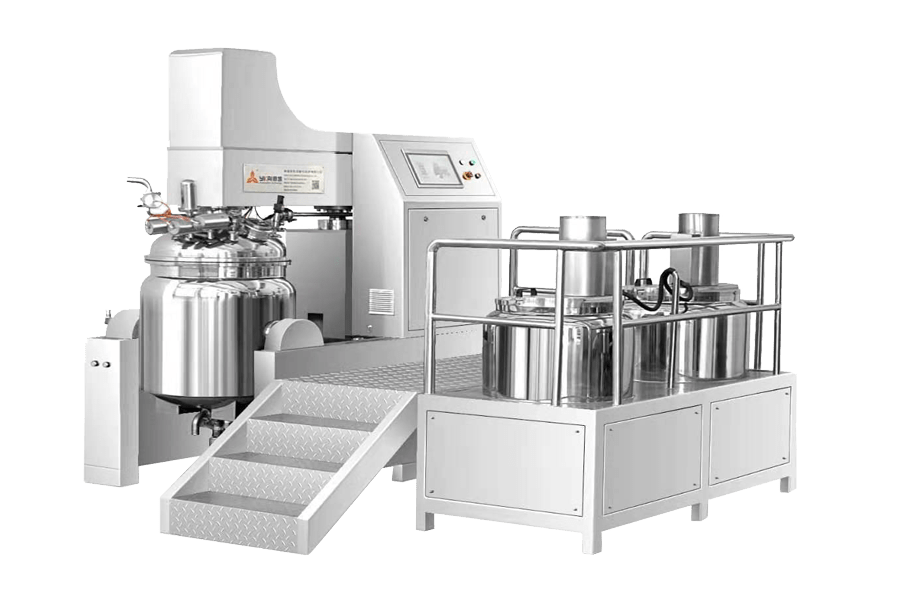

There are many types of emulsifiers, such as vacuum emulsifiers, hoisting homogenizing emulsifiers, pipeline high-shear emulsifiers, internal and external circulation emulsifiers, no matter which style, the core of emulsification is the rotor system of the emulsifying machine. Through this pair of interlocking stator and rotor connected to the engine and performing high-speed rotation, the material passing through the narrow gap between the stator and rotor is sheared, dispersed, and impacted to obtain stable and high-quality products. The emulsifier is a fluid mixing equipment, which is widely used in the fields of pharmacy, chemical industry, food, daily chemical, energy, and new materials. For example, emulsifier equipment is used in the production of emulsions, ointments, gels, and other products in the pharmaceutical industry.

Development status of emulsifiers

In the past, emulsifiers used in various industries generally chose manufacturers’ brands in other countries. With the introduction of emulsification and homogenization technology in the 1990s, the development of domestic emulsifiers ushered in a flourishing spring. In addition to the introduction of foreign technology, emulsifier manufacturers also focused on the development and update of equipment technology. Customers in the pharmaceutical, chemical, food, and other industries at home and abroad have also paid more attention to the emulsifiers of China, which have been recognized by more and more end customers, and the application range has become wider and wider. Whether it is a leader in the pharmaceutical or food industry, they are actually paying attention to the development of domestic emulsifier equipment, especially some big brand manufacturers pay more attention to equipment research and technological breakthroughs because the industry’s production processes are constantly developing breakthroughs every day. The place that can change the technological breakthrough is the change of hardware facilities. Some manufacturers pointed out that under the current background of fierce competition in the pharmaceutical market, hardware facilities can be said to be a breakthrough that companies are looking for.

The future development trend of emulsifiers

The rapidly changing market has prompted changes in the entire industry chain. For the application industry of emulsifiers, they need higher-quality products, more efficient products, and safer and sanitary products. All these changes require emulsifier manufacturers to meet their requirements. All of these have prompted the needs and requirements of emulsifiers to continue to change. With the application industry constantly pursuing high-quality products, the emulsifier equipment market is facing a situation where opportunities and challenges coexist, prompting emulsifier manufacturers to keep pace with the times, strengthen research and development breakthroughs, and promote the continuous development of the emulsifier industry. From the perspective of the industry, the entire process of emulsifier products from design, procurement, production, assembly, and commissioning must meet standards. Some emulsifying machine manufacturers have continuously introduced various new products that meet the needs of the industry by strengthening and insisting on innovative research and development in order to improve the emulsification effect, equipment service life, and stability.

For example, Yekeey has innovated a nano vacuum emulsifier based on the previous micro emulsified. The upgraded equipment is more suitable for the emulsification, dispersion, and crushing of soft tissue particles. When used, this emulsifier first processes the product to 200nm-2um, and the additional vacuum system can also eliminate bubbles in the material, combined with the vacuum degassing system of the equipment, so as to achieve a better emulsification effect. In addition to insisting on product innovation, manufacturers of emulsifier made in china also need to insist on optimizing and improving details. For example, some manufacturers have optimized the design of the mixing device and the transmission shaft, and avoid the sanitary dead angle caused by too many flanges, screws, and other connecting parts in the design of the mixing device. The mixing shaft adopts a high-performance transmission shaft, unique design, and precise production, which guarantees high torque output, no running deviation, perfect seal, and long service life of the bearing.

It can be seen that some emulsifier manufacturers have made some breakthroughs in technology and craftsmanship. But on the whole, although the varieties of emulsifiers in China are relatively complete, and the development of host products is better, short delivery time, and flexible and timely services. However, in some technical fields, there is still a certain gap with foreign equipment. Therefore, as domestic emulsifiers are developing towards high-end need industry enterprises to strengthen innovation and R&D, improve automation and informatization, and constantly breakthrough pain points to help the development of the domestic emulsifier industry to a higher level.