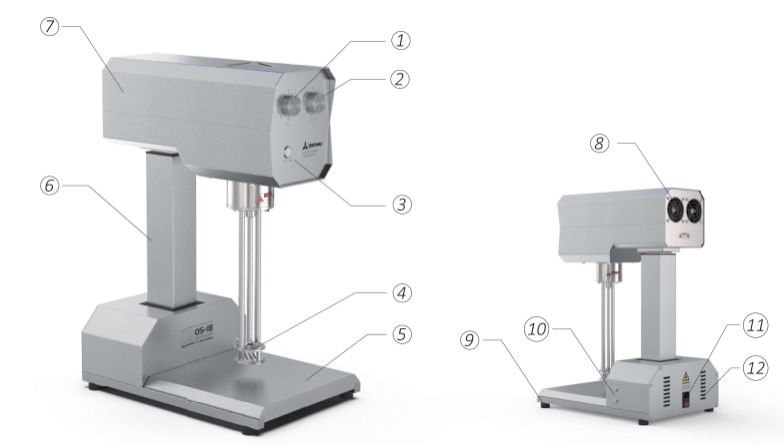

| 1. Timing knob

The timer of 0-30 minutes, 40mm aluminium alloy knob, anti-skid surface treatment, even wearing gloves can be accurately adjusted. |

2. Speed control knob

600-8000 rotational speed regulation, 40mm aluminum alloy knob, surface anti-skid treatment, even wearing gloves can be accurately adjusted. |

3. Mean Start Button

Stainless steel self-locking button, excellent feedback experience, corrosion resistance, easy to clean. |

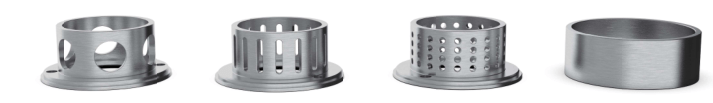

4. High shear mean working head

Stainless steel self-locking button, excellent feedback experience, corrosion resistance, easy to clean. |

| 5. Stainless steel bracket

SUS304 material pallet, can be quickly disassembled, easy to flush sticky materials, and pallet can be optionally replaced by heating module. |

6. Lifting column

SUS304 material, can dock at any position |

7. All Stainless Steel Material

The whole mechanism and shell are made of SUS304 material of food grade, which is beautiful, sanitary, corrosion-resistant and easy to clean. |

8. Cooling Fan

With the top ventilation hole to form a complete duct to ensure the stable operation of homogeneous motor components. |

| 9. Rubber foot

It has the function of anti-skid and shock absorption. |

10. Lift button

Stainless steel push button, excellent experience of operation feedback, corrosion resistance, easy to clean. |

11. Power Supply

220V single-phase connection with power supply indication, cut off switch and fuse |

12. Fin type radiator

Make sure the parts in the cabinet of ventilation and cooling, prolong the service life of electrical parts. |