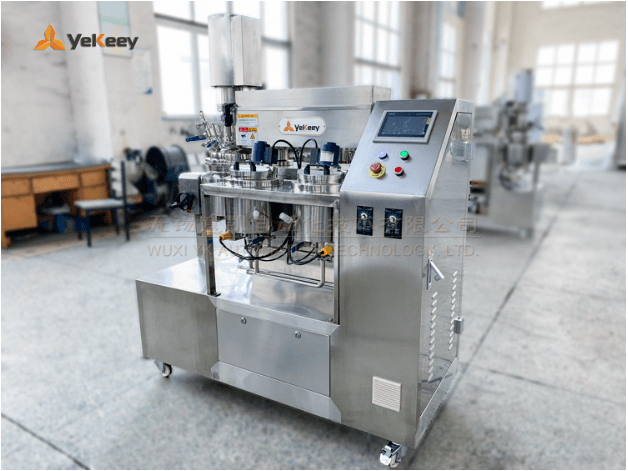

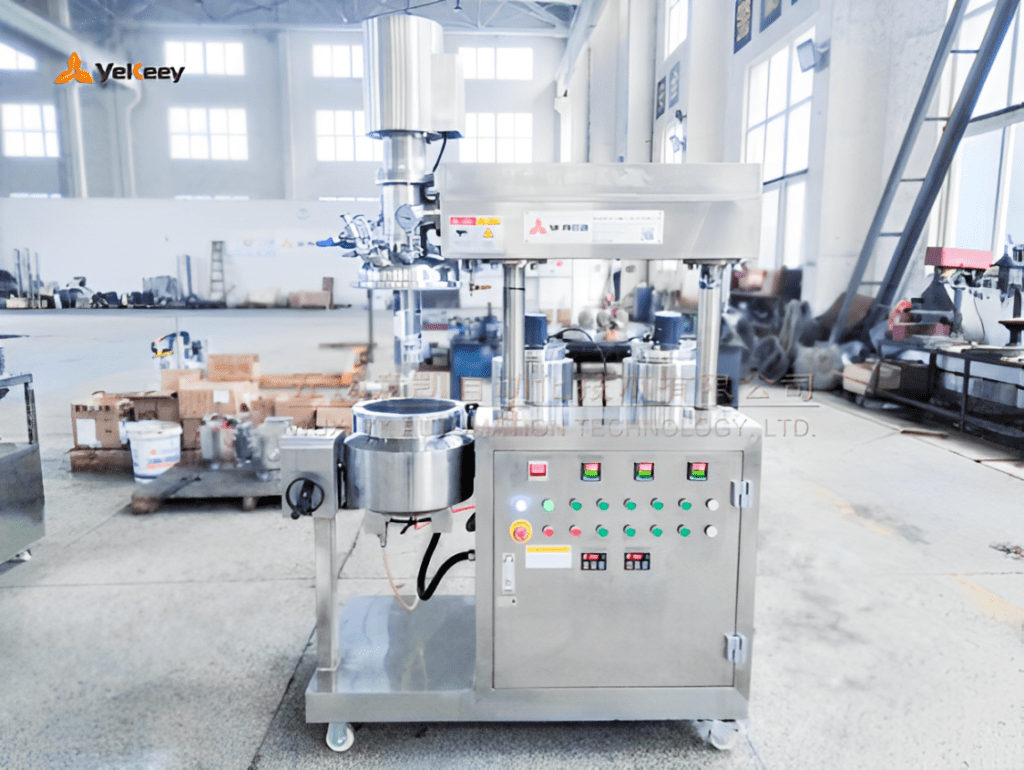

In the process of preparing suspension, emulsification and homogenization dispersion are very important, so you urgently need such an suspension emulsifier.

1. Applications

Suspension emulsifier is a widely used equipment in industries such as pharmaceuticals, cosmetics, and food. It is mainly used to mix two or more immiscible liquids together to form a uniform emulsion or suspension.

(1) In the pharmaceutical industry, suspension emulsifiers are widely used to prepare various oral liquid drugs, such as suspensions, emulsions, syrups, etc.

(2) In the cosmetics industry, suspension emulsifiers also play an important role. It can mix raw materials with different properties such as oil and water together to form a delicate and uniform emulsion, thereby improving the stability and effectiveness of cosmetics.

(3) In addition to the pharmaceutical and cosmetics industries, suspension emulsifiers have also been widely used in the food industry. For example, when making beverages, dairy products, seasonings, and other products, this device can mix different raw materials together to form a uniform and delicate suspension or emulsion, thereby improving the taste and quality of the product.

(4) At the same time, suspension emulsifier can also perform heating, cooling, vacuum and other operations as needed to meet the production needs of different drugs.

Overall, the suspension emulsifier is a very practical equipment with a wide range of applications, which can meet the production needs of different industries. With the continuous progress of technology and the continuous development of the market, it is believed that this equipment will play a more important role in future production.

2. Working Principle

Suspension emulsifier’s working principle is to mix different liquids together through high-speed stirring and shear force, achieving a uniform dispersion effect.

In addition, the device can adjust parameters such as stirring speed, temperature, and time according to different formulas and product requirements to achieve the best emulsification effect.

3. Features

Suspension emulsifier has the characteristics of high efficiency, stability, and easy operation, and is one of the indispensable important equipment in modern production.

4. When using a suspension emulsifier, it is necessary to pay attention to some operational details and maintenance.

(1) Firstly, before operation, it is necessary to carefully read the user manual of the device, understand its working principle, operating methods, and precautions.

(2) Secondly, it is necessary to strictly control parameters such as stirring speed, temperature, and time during the operation process to ensure the quality and stability of the product.

(3) In addition, it is necessary to regularly clean and maintain the equipment to ensure its normal operation and service life.

(4) In addition to the above precautions, it is necessary to select and configure equipment according to actual needs to improve production efficiency and reduce production costs.

(5) Different production and product requirements require the selection of different models and configurations of suspension emulsifiers.

I do not even know how I ended up here but I thought this post was great I dont know who you are but definitely youre going to a famous blogger if you arent already Cheers.

I do not even know how I ended up here but I thought this post was great I dont know who you are but definitely youre going to a famous blogger if you arent already Cheers.

Your blog is a constant source of inspiration.