CIP cleaning system can be used for cleaning of conveying equipment, material pipelines and filling equipment in the bakery and confectionery such as cleaning and disinfection of equipment and pipelines of dairy, beverage, beer, and pharmaceutical production lines before or after work to ensure that strict hygiene requirements can meet the standards.

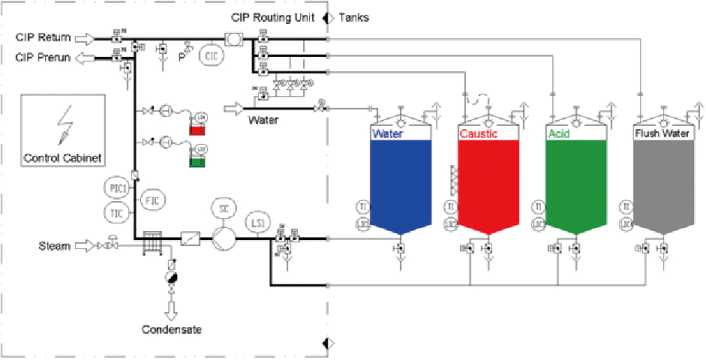

The cleaning-in-place system (CIP) equipment is a cleaning circulation system that generally consists of a cleaning liquid storage tank, a liquid conveying pump, pipelines and pipe fittings, a cleaning head, a circulating pump, a program control device, including the equipment to be cleaned.

This equipment uses a centrifugal pump to transport the cleaning liquid in the material pipeline and equipment container for forced circulation to achieve the purpose of cleaning. Therefore, there is no need to dismantle the pipeline and equipment, which can improve the utilization rate of the equipment, and has the characteristics of high work efficiency, reliable cleaning effect and good reproducibility. The operation process is carried out in the closed space, which reduces the labor intensity of workers with the features of high hygienic requirement and convenient operation.

Compared with traditional cleaning methods, the advantages of CIP cleaning methods are:

- The cleaning effect can be repeatedly verified.

- Save operation time and improve efficiency.

- Save labor and safety.

- Save pharmaceutical water.

- Modular production, and can realize FAT.

- Environmental protection and energy saving, easy to install and operate.