Laboratory Vacuum Homogenizing Emulsifying Equipment

.jpg)

-

Laboratory emulsification

-

Small-scale emulsification production

Product Advantages

-

Programmable parameters

It can deal many materials in various tests and productions.

-

Shorter batch time

It can quickly establish a dispersed emulsification system and quickly mix a large amount of material.

-

Lower Cost

Shorten cleaning time and reduce maintenance requirements, optimize and streamline costs to achieve high production.

Working Principle

- The production raw materials are directly pumped into the homogenization head through vacuum, emulsified, and then enter the main tank through a circulating pipeline, and wait to enter the homogenization head again.

- The specially designed scraping wall mixing ensures the mixing effect and high heat exchange efficiency.

homogenizer head

Some Cases Show

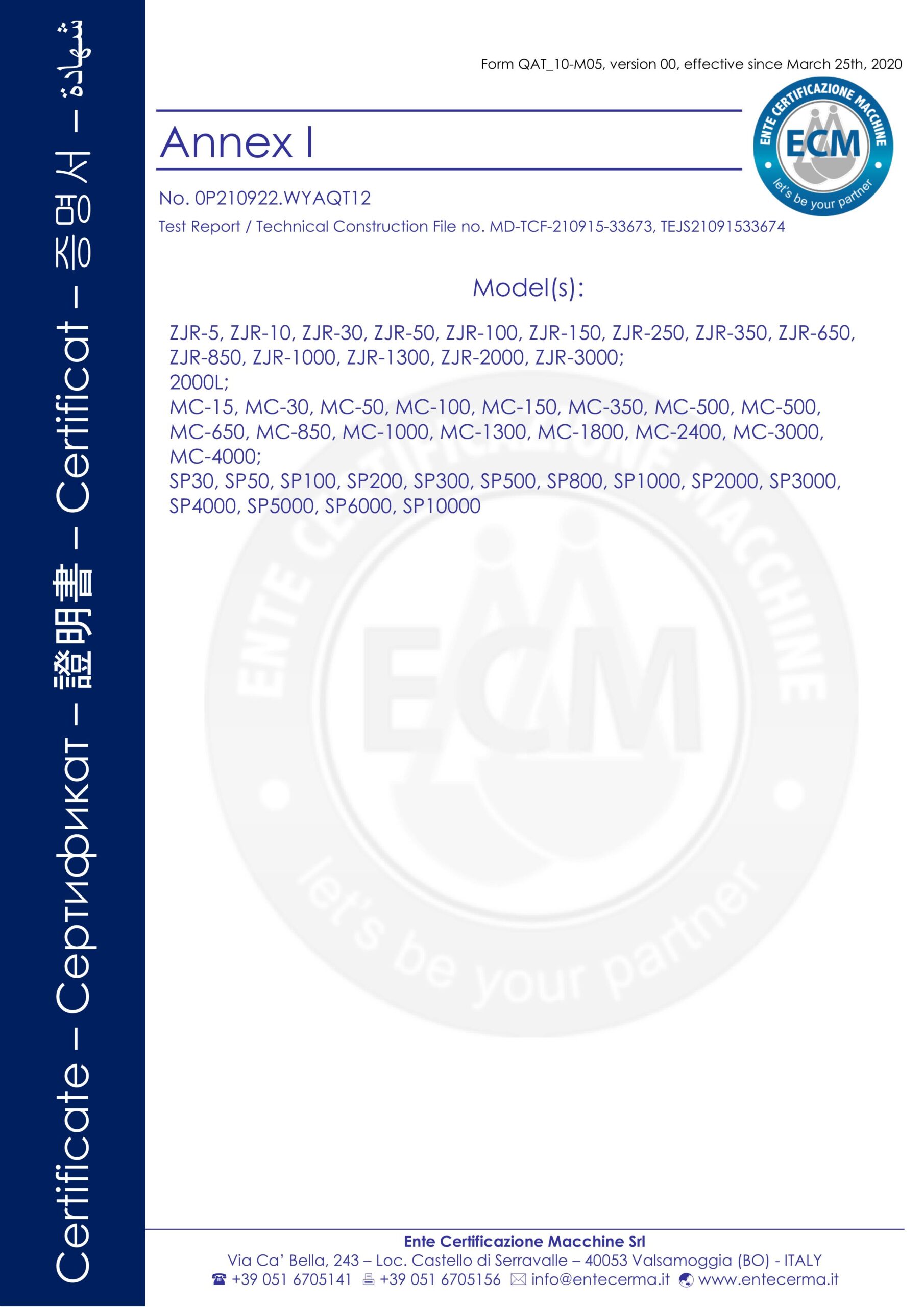

Certification

Product Parameter

|

Model |

Design volume(L) | Max. Useful volume (L) | Min. Useful volume(L) | Dimensions (L*W*H/mm) |

| ZJR-5 | 6 | 4 | 2.5 |

1400*600*1700(2000) |

|

ZJR-10 |

11 | 8 | 5 | 1500*600*1750(2000) |

| MC-15 | 15 | 12 | 3 |

1400*900*1600(1650) |

|

SXJ-10 |

10 | 8 | 1.5 |

990*910*2360 |