Industry hot oil type heating mold temperature controller is also called mold temperature control machine.is widely used in chemical reaction kettle and other industries.

Reactor oil heater features

- Return oil temperature display function

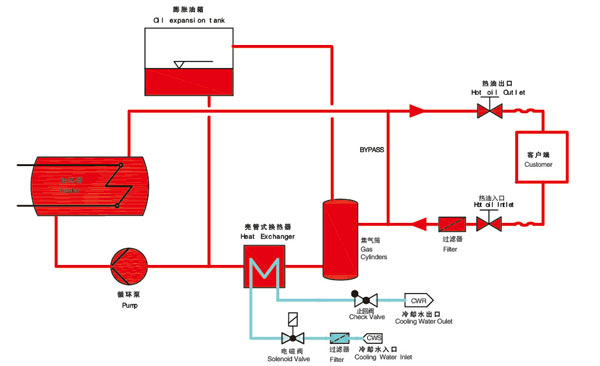

- automatic exhaust function at startup

- heating power switching function

- hot oil BY-PASS pressure relief circuit

- Multi-point temperature control unit can be customized

- oil pump horsepower and heating power can be customized

- Temperature control accuracy: PID±1°C

- Isolated electrical control box. Extend the service life of electrical appliances\

- The electrical appliances adopt OMRON. FUJI. TE. LG. MOELLER. ABB. WEST.

- Temperature control range: inlet oil temperature +15℃→300℃

- 304 stainless steel or carbon steel integrated pipeline to reduce pipe resistance and rust

- The temperature control meter adopts OMRON or WEST microcomputer dual group P.I.D control, touch-sensitive internal storage and automatic calculation, accurate and reliable, saving more than 35% of electricity

- Complete safety protection, fault display, maintenance. Maintenance does not require professionals. Machine specifications

- explosion-proof device (optional)

- Blowing and oil return function (optional)

- instant cooling off function (optional)

- RS485 communication function, realize automatic management. (optional)

- Control method: Imported microcomputer or PLC control (optional)