Customers from the Sino-Japanese joint venture Dalian Food “Gourmet Factory” from 39°north latitude visited YeKeey before and wanted to know about YeKeey’s mayonnaise making machine. After understanding, the customer compares the MC series vacuum homogenizing emulsifiers Satisfied, he ordered a 100L MC series clamshell recirculation vacuum homogenizing emulsifier. After the production of the emulsifier is completed, we invite customers to come to the factory to inspect and test the machine. Yesterday, the customer representative came from Dalian to Wuxi for inspection and test machine.

The customized MC-100 clamshell recirculation vacuum homogenizing emulsifier is a medium-sized emulsifier that has the highest reputation and sales volume this year. Its batch processing capacity is 10-80 kg, and the batch preparation time of mayonnaise is within half an hour (the specific process is different). Let’s take a look at the process and effect of the on-site test machine.

Test machine process and effect

1.Pretreatment water-oil pot feeding

2.Feeding of main emulsifying pot

According to customer requirements, first, pour the material from the semi-open opening of the pretreatment water and oil pot into the pretreatment water and oil pot, and feed the material at the entrance of the main pot hopper. Customers can use vacuum suction to feed materials in actual production to ensure the cleanliness of materials.

3.PLC touch screen control system demonstration

This emulsification machine is a medium-sized machine in the MC series of YeKeey. Its characteristic is that it adopts an advanced PLC touch screen control system and is equipped with an automatic pneumatic valve, which can realize intelligent emulsification and mixing operation.

Advantage 1: The operation is controlled by the PLC computer, and the relevant process data can be recorded according to the user’s requirements;

Advantage 2: Real-time monitoring of a series of data such as the temperature, homogenization, mixing speed, time of the main emulsification pot, water and oil pot at that time;

Advantage 3: Computer touch screen control, integrated operation, reduce work intensity, the unit is beautiful and generous; the machine is equipped with an emergency stop button, which can be shut down with one button.

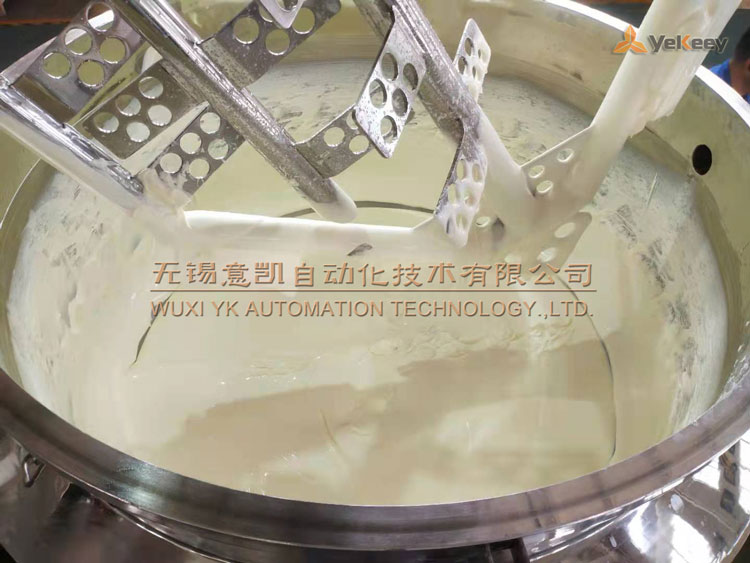

4.Mayonnaise emulsified in the main emulsifying pot

Not much to say about the emulsification process, it is very easy to complete the emulsification after the parameters are set. The customer representative carefully observed and recorded the entire emulsification process and was very satisfied with the emulsification effect. The following is the scene picture of the emulsification process:

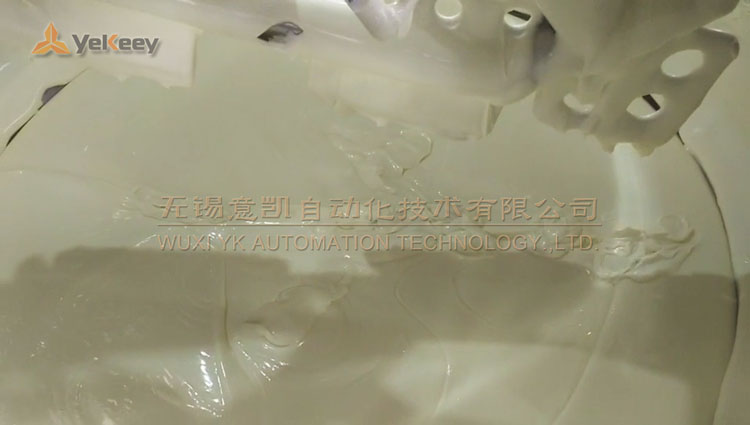

Pretreatment water oil pot Disperse mixing

The material in the water-oil pot is vacuumed into the main emulsifying pot

The effect of mayonnaise out of the pot after emulsification

The effect of mayonnaise out of the pot after the emulsification is over

5.Rotor pump feeding

During the test acceptance process, the customer carefully understood the working principle and operating specifications of this model of emulsifier and provided us with valuable opinions in terms of technical upgrades and customer needs. Before the equipment leaves the factory, inviting customers to inspect the goods and solicit customer opinions and feedback is a tradition that our company adheres to. It is also an opportunity for us to listen to customer needs and solve customer pain points. It is also the source for us to deliver fresh blood and continuously improve and innovate our products. Here, I am very grateful to our customers for their trust and frankness to us, and for providing us with valuable opinions and suggestions. Looking forward to progress and grow together with you in the future. Thank you for your trust and support. We are also willing to send out more detailed test procedures for customers for your reference. If you want to know more about the equipment effects or functions, you can search on Douyin [Wuxi YeKeey Automation Technology Limited Company] Check out the video of the test machine process!