“People eat food for the day, eat milk for the first”, cheese can also be called cheese, it is a fine product in dairy products, and is often referred to by the industry as “the pearl of the dairy industry.” In some areas where animal husbandry is more developed, local residents often eat steak, cream, cheese and other foods. Cheese is popular with its rich taste and high nutritional content. It is understood that more than 130 countries in more than 170 countries produce cheese. At present, the total cheese production in the world is nearly 20 million tons. What is needed for emulsification and stirring from raw materials to cheese preparation? What about cheese production equipment?

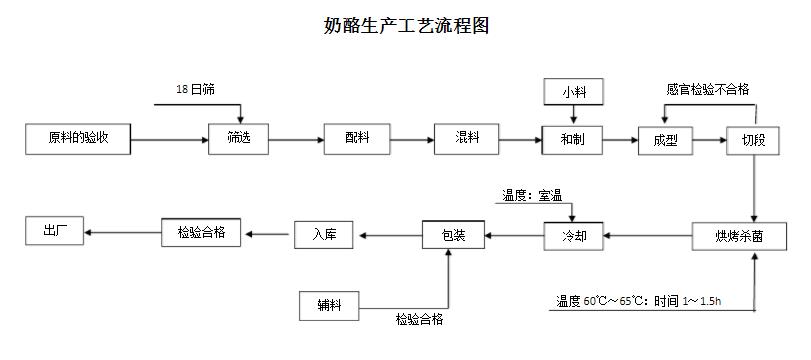

First, the cheese production process

The cheese production process is shown in the figure: raw milk reception → standardization → sterilization → infusion of cheese trough → addition of starter → addition of rennet → curd → cutting → stirring mold → whey → mold release → chopping → Salted → mature.

Raw milk requirements: fresh no anti-milk, no bad smell, no doping makes false, fat index per 100g raw milk is 3.10% – 3.30%, protein is 2.95% – 3.10%, pH is 6.40-6.80;

Standardization: Normally based on the fat content of the final product, the raw milk is standardized by separating the cream or adding skim milk to make the final protein: fat = 0.90: 1.00.

Sterilization: Feta cheese is sterilized by means of 72 ° C / 16 s or 62 ° C / 30 min.

Adding a starter: cooling the sterilized raw material milk into a cheese trough, adding a starter composed of Lactococcus lactis subsp. lactis and Lactococcus lactis subsp. and stirring evenly in a stirred emulsifier of the cheese mixture, and pre-fermentation for 1h.

Add chymosin: dilute the rennet with 10 times pure water to form an enzyme solution, mix it well by the pretreatment tank of the stirring emulsifier, then inject it into the emulsification tank, then stir it in the emulsification tank for 3-5 minutes, the whole curd time is 45-60min.

Cutting: Firstly use the cheese cutting knife to cut horizontally, then cut vertically, and finally cut up and down, cut into small squares, the cutting time is controlled within 5min, and the cutting is allowed to stand for 3-5min.

Stirring: Can start stirring when the curd granules reach the appropriate size. The whole mixing time is controlled within 20 min. Then, the curd granules and whey are poured together into the special mold of Feta cheese.

Press: Press 3-5h, this stage will have an important impact on the hardness, acidity and humidity of the finished Feta cheese.

Salting: When the pH of the clot reaches 4.70, it is taken out from the mold, cut into cubes with a side length of about 10 cm and a weight of about 100 g by using a cutter, and then the cut cheese pieces are soaked in the 12%-16% saline solution, the time is 14-16h, the temperature is controlled at 16-18 ° C, so that the Feta cheese salt concentration reaches 2% -3%.

Maturity: soak the cheese block in 6%-8% saline solution, add 0.06% calcium chloride and citric acid, make the pH of the solution reach 4.60, mature at 8-10 °C for 60 days, then store at 2-4 ° C.

Second, the cheese mixing equipment uses a cheese stirring emulsifier From the process flow, we can see that the cheese process has many links from raw materials to forming, and the mixing process is the key link. In the mixing process, the sterilized raw material milk is injected into the emulsification tank. At this time, the fermenting agent needs to be added, and the equipment is evenly stirred by the cheese stirring emulsifier. In the industrial production, the quality of the cheese and the uniformity of stirring and dispersion are high. Choose the right cheese production equipment can improve the consistency of the finished product. The cheese blending emulsifier produced by Yekeey has many successful cases in cheese producers at home and abroad. Many foreign customers have learned about our equipment online, and rushed to China in the distance to experience the test results. The above picture is some of the live shooting pictures of the customer test the machine. If you want to know more about our cheese stirring emulsifier, welcome to contact Yekeey!

From the process flow, we can see that the cheese process has many links from raw materials to forming, and the mixing process is the key link. In the mixing process, the sterilized raw material milk is injected into the emulsification tank. At this time, the fermenting agent needs to be added, and the equipment is evenly stirred by the cheese stirring emulsifier. In the industrial production, the quality of the cheese and the uniformity of stirring and dispersion are high. Choose the right cheese production equipment can improve the consistency of the finished product. The cheese blending emulsifier produced by Yekeey has many successful cases in cheese producers at home and abroad. Many foreign customers have learned about our equipment online, and rushed to China in the distance to experience the test results. The above picture is some of the live shooting pictures of the customer test the machine. If you want to know more about our cheese stirring emulsifier, welcome to contact Yekeey!