It’s been said that details matter, and it’s true in cheese production, where even small differences in cheese production equipment can have a big impact on the quality of your product.

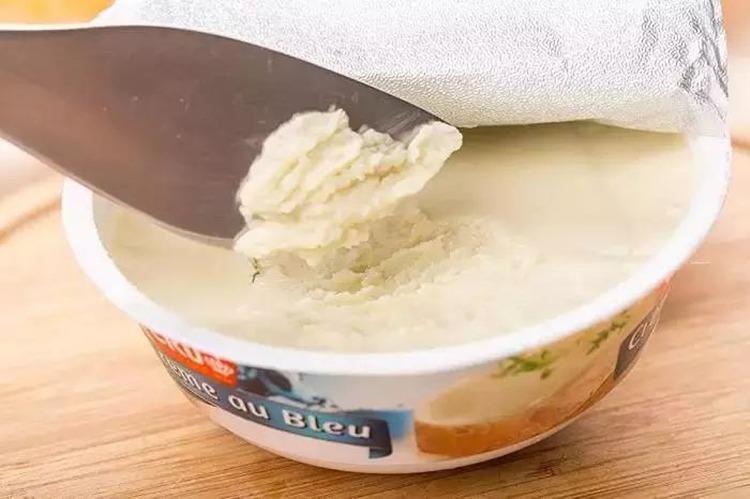

Spreadable cheese processing relies on two key technologies, they are heating and mixing. But the equipment that provides these process steps varies widely. So, what kind of cheese production equipment do you need when choosing? What should you pay attention to?

Attention to choosing cheese production equipment

The first step in the processing line is mixing. Efficient mixing is critical when producing reconstituted spreadable cheese varieties with powdered ingredients. A lump-free dissolution of all powders is essential, as is good emulsification of the added cheese ingredients.

Traditional emulsifying mixers are good at handling 100% cheese ingredients, but they are not optimized for powders. The YeKeey high-shear emulsifying mixer can handle all cheese ingredients, it has specially designed knives on top of the mixing unit for cutting and grinding cheese, combined with a rotor-stator system below for dissolving powder and emulsifying cheese products.

The frame-type scraper of the mixing emulsification unit and the disc-type large circulation design of the stator and rotor can transport the product down to the rotor-stator system of the high-shear emulsifying mixer through mechanical force. Once the product enters the mixing unit of the emulsification tank, the rotating rotor squeezes it through the small holes in the surrounding stator. This high shear effect disperses the powder into the liquid very efficiently and emulsifies the cheese product instantly. This high shear effect disperses the powder into the liquid very efficiently and emulsifies the cheese product instantly.

Achieve consistent quality and save money

If you had powders in a traditional mixing machine, the stabilizers would clog together and you’d see fish eyes in the product, but with high shear, you can mix stabilizers like starches and emulsifiers very efficiently, which not only consistent product quality ensured, it also saves money because in most cases you use fewer additives such as emulsifying salts and stabilizers. The high shear effect saves expensive raw materials, thereby reducing your production costs. It can also go from high shear to low shear in the same process, which is useful if you want to add any additives like granules or flavors. By switching to low shear, you can lift the stator, thereby maintaining the integrity of the pellets.

Uniquely, the YeKeey high-shear emulsifying mixer can also heat treat the product. For batch-produced pasteurized spreadable cheese, this means you can do whatever you want in the emulsifying mixer. For food sauce production, our emulsifying mixers are the most versatile choice, with the versatility to handle everything in the same unit. For certain types of spreadable cheese and batch lines, this is a huge advantage.

Turn up the temperature

Heating is a standard step in the manufacture of spreadable cheese. First, you have to pasteurize the cheese base to get rid of unwanted bacteria. If your spread is intended for ambient delivery, it will also require UHT processing. A variety of heating methods can be used to remove spores and ensure long shelf life.

In heat treatment, the heat load is the primary consideration. A heat exchanger that can heat your product to the desired temperature in the shortest possible time will give you a higher product quality for the same shelf life as a model that takes longer to heat up. Shorter heating times mean lower heat loads, which are gentler on your product. Gentle processing better preserves the integrity of taste, flavor, and color particles, improving the way your end consumer experiences your product. YeKeey’s various heating methods can be optimally selected according to your output, equipment cost, existing conditions, and other factors.

To learn more about how YeKeey high-shear emulsifying mixers can help you maximize the versatility and efficiency of your operations, please contact customer service online or call us.