What questions about high-shear emulsifier customers inquire

When many customers inquire about our products, they often ask about equipment related to particle size.

For example:

- What is the smallest particle size that the high-shear emulsifier can achieve?

- We are an oil and water system. Can your high shear homogenizer homogenize the material to an average particle size of fewer than 2 microns?

- What is the particle size of the particles after shearing and homogenization?

- What is the principle of reducing the particle size by the high-shear emulsifier?

And soon, a large number of customers have requirements for the particle size of the product. What is the impact of the diameter on the product, and why should we pay attention to the particle diameter of the product?

An important factor —The particle size control

Many high-quality products have many determinants of their quality. The particle size control in the high-shear emulsifier production process is an important factor and one of the most important key factors.

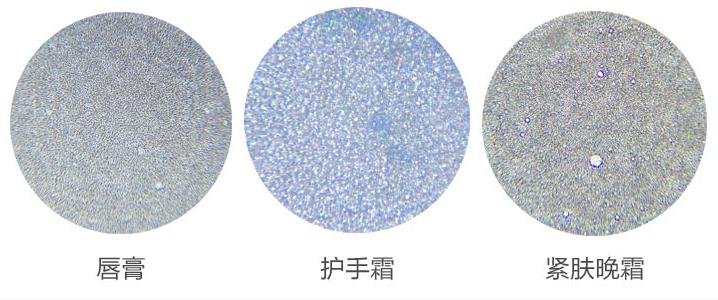

For example one of our customers is making paste products, and they require that the particle size can be controlled within (the range of 0.5 micron-20 micron reaches more than 80%). This can achieve easy absorption, effectively improve product stability, product uniformity, and have good reproducibility requirements. The raw and auxiliary materials of the ointment should be evenly distributed, with a fine appearance, and no roughness when applied to the skin; the ointment should have a suitable stable viscosity and be easy to be applied to the skin or mucous membranes; the ointment has stable properties and no oil-water separation.

The particle size may have an impact on the material mixing uniformity of the process, as well as the dissolution behavior and stability of the formulation because it is related to product quality and requires better attention.

In addition to cosmetic creams, in other industries, the impact of particle size on product quality also exists:

- The grinding time and grinding medium in the cement grinding process affect the cement particle size, which in turn affects the cement strength and setting time.

- In the ceramic industry, the size of the raw material particles influences the physical properties after sintering.

- The particle size of the catalyst directly affects the efficiency of the chemical reaction.

- In the pharmaceutical industry, the size of drug particles controls the dissolution speed and effectiveness.

- The shelf life and taste of food are closely related to particle size.

In order to meet the needs of customers, our requirements for particle size, the high-shear emulsifier equipment produced by YeKeey, our high-speed shear system design, can make the product materials reach nano-scale shear particle size, to meet customer needs.

The high-shear emulsifier covers from laboratory research and development to industrial mass production, suitable for-biopharmaceuticals: ointments, ointments, gels, suspensions; cosmetics: creams, lotions, toothpaste, liquid washing products; food: salads The research and development and production of products such as sauce, mayonnaise, cardeda sauce, pastry sauce, seasoning liquid, food additives, butter, cheese, chocolate sauce, bread, and moon cake fillings.