November 30th afternoon, entrusted by clients, we did a trial of ophthalmic gel making. And this time we did the trial on our newly designed mixing equipment —Mixcore Recirculation Mixing Plant. Here we share the whole process of the trial. If you have any similar needs, welcome to contact us. You can visit our factory personally, and we can offer you free trial!

According to the trial plan, we prepared the materials for the trial in advance.

Making gel by Mixcore mixing equipment

The hydrogel is a raw material used in ophthalmic gel making. It has high demands on sanitary cleaning of the mixing equipment . Mixcore Recirculation Mixing Plant can mix, homogenize and disperse in high efficient. This machine can also heat and cool the materials; its design of powder feeding method can make the production more sanitary, clean and efficient. Here we first added water into this mixing equipment , then close it and open the vacuum and homogenizer.

When the vacuum degree reaches a certain value, close the vacuum and open the feed inlet. (You can add liquid or powder through the feed inlet.) Pump the glycerol into Mixcore, open the emulsifier. After a certain time, turn off the emulsifier.

Then dissolve the power materials into the water, adjust the speed of mixing, open vacuum and feed inlet, add the powder and liquid materials slowly through the feed inlet.

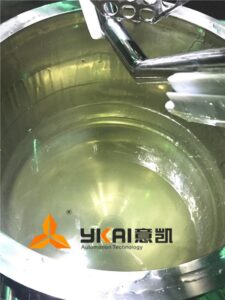

After the homogenizing and dispersing for a certain time, turn off the equipment, open the cover, we finally successfully got the hydrogel—the material which customer want in this trial. The picture of finished product is as follow:

Through this process of making hydrogel, we can obviously feel that the Mixcore has the advantage of high-efficient, sanitary and clean. Therefore, Mixcore is the very suitable machines for producing cream, gel and suspension liquid.