With the increasing of many consumers’ health awareness and the demand in the food market, mayonnaise is loved by more and more people. Therefore, more and more manufacturers are involved in the production and sale of mayonnaise. Globally, the consumer market of mayonnaise is mainly concentrated in North America, Europe, Asia, and other regions. Therefore, manufacturers have more and more demand for mayonnaise production equipment, and the requirements for quality are also higher and higher.

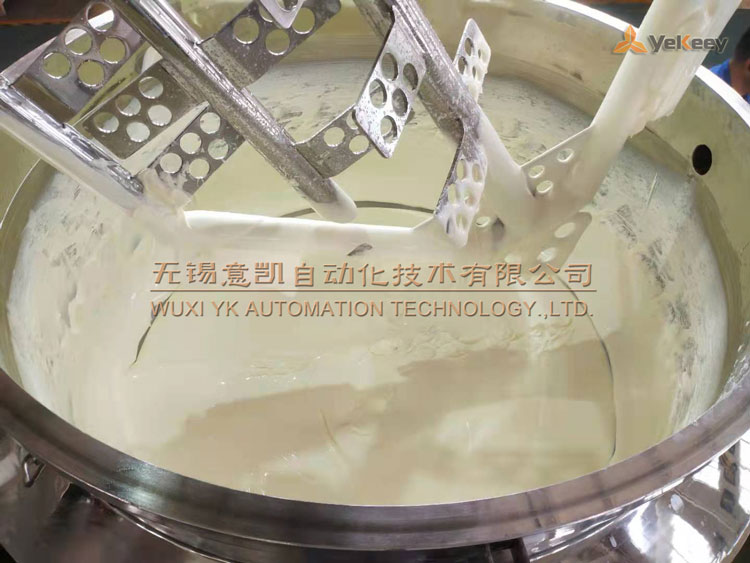

As a professional emulsifying machine manufacturer, YeKeey Automation has helped many mayonnaise manufacturers to produce healthy, fine, and high-end mayonnaise for so many years. Recently we received feedback from Spanish customers who purchased a mayonnaise line. In the workshop of a sauce manufacturer in Lario, northern Spain, the vacuum emulsifiers in two mayonnaise production line equipment deliver about 1,000 kg of prepared mayonnaise every half hour to a buffer tank, which passes through sanitary pipes connected to the filling machine in the room next door to the factory. Advanced mayonnaise production lines are highly automated, allowing for smooth and efficient mass production. The flexible solution produces batch after batch of smooth, sparkling mayonnaise with great accuracy and consistency.

As a professional emulsifying machine manufacturer, YeKeey Automation has helped many mayonnaise manufacturers to produce healthy, fine, and high-end mayonnaise for so many years. Recently we received feedback from Spanish customers who purchased a mayonnaise line. In the workshop of a sauce manufacturer in Lario, northern Spain, the vacuum emulsifiers in two mayonnaise production line equipment deliver about 1,000 kg of prepared mayonnaise every half hour to a buffer tank, which passes through sanitary pipes connected to the filling machine in the room next door to the factory. Advanced mayonnaise production lines are highly automated, allowing for smooth and efficient mass production. The flexible solution produces batch after batch of smooth, sparkling mayonnaise with great accuracy and consistency.

Advantages of vacuum emulsifier

- The air bubble content of the emulsified body can be reduced to a minimum, and the surface smoothness of the emulsified body can be increased.

- As the stirring and emulsification are carried out in a vacuum state, the materials will no longer be lost due to evaporation, and the contact between the emulsified body and the air is reduced and avoided, the contamination of the product by bacteria is reduced, and the product will not be deteriorated due to oxidation.

- Under vacuum conditions, the speed of the stirrer is accelerated, which improves the emulsification efficiency.

In the production of mayonnaise solutions, the emulsifier equipment produced by YeKeey can combine the emulsification tank with the pretreatment mixed water tank in various ways through pipeline valves, and can also pass the discharge pipeline and equipment to the downstream filling unit.

“It’s an advanced process that delivers perfect quality every time,” says the boss of this mayonnaise manufacturer, who oversees the company’s national sales and marketing. The boss has a high evaluation of YeKeey’s mayonnaise production line. Recently, he and his sister took over the company founded in 1995 by their father. The customer’s boss said that the company’s food sauce production equipment has been using second-hand machines from the market to work in small warehouses. With the continuous development of the market, the quality and output of the original second-hand mayonnaise production equipment became less and less able to keep up with the market demand. Later, the customer decided to upgrade the equipment.

Fortunately, YeKeey company’s strength and equipment passed the inspection of the customer, and the customer purchased a complete set of the mayonnaise production lines from YeKeey.Through a period of production, the company has continued to increase production and quality has risen to a new level and has now become the leading manufacturer of mayonnaise in Spain. YeKeey’s vacuum emulsifier equipment and other supporting whole production line equipment serve the mayonnaise food market in Spanish.

Thank customers for their trust and support, I wish customers a prosperous business development.