-

What problems will happen during using a homogeneous emulsifying machine? How to solve?

Homogeneous emulsifying machine may encounter different problems during use, and corresponding solutions can be taken:

(1) Difficulty or inability to start the machine:

- Reason: This may be caused by power failure, motor damage, circuit failure, and other reasons.

- To solve this problem, it is necessary to check the power supply and circuit of the equipment, as well as whether the motor is working properly. If faults are found, they need to be repaired or replaced in a timely manner.

(2) Abnormal sound during machine operation:

- Reason: This may be caused by damaged bearings, loose transmission belts, gear wear, and other reasons.

- To solve this problem, it is necessary to inspect the transmission system and bearings of the equipment. If any faults are found, they need to be repaired or replaced in a timely manner.

(3) Excessive temperature during machine operation:

- Reason: This may be caused by cooling system malfunctions, insufficient lubricating oil, and other reasons.

- To solve this problem, it is necessary to inspect the cooling and lubrication systems of the equipment. If any faults are found, they need to be repaired or replaced in a timely manner.

(4) Poor emulsification effect:

- Reason: This may be caused by impeller damage, inappropriate rotation speed, unreasonable material liquid ratio, and other reasons.

- To solve this problem, it is necessary to check the parameters of the impeller and speed of the equipment, as well as the proportion and properties of the material and liquid. By adjusting the parameters or optimizing the material properties, the emulsification effect can be improved.

(5) Poor stability of emulsion:

- Reason: The emulsion may lose stability due to various reasons, such as high temperature, inappropriate pH value, insufficient emulsification time, etc.

- Controlling the temperature and pH value of the emulsion, adjusting the emulsification time, and other measures can improve the stability of the emulsion.

(6) Difficulty in operation:

- Reason: The operation of the emulsifier may be complex and require professional knowledge and skills. If operated improperly, it may lead to equipment failure or poor emulsification effect.

- Professional training or guidance is required to master the correct operating methods.

(7) Equipment leakage:

- Reason: This may be caused by worn seals, loose pipeline connections, and other reasons.

- To solve this problem, it is necessary to check the sealing components and pipeline connections of the equipment, replace the sealing components or adjust the pipeline connections in a timely manner.

(8) High equipment vibration:

- Reason: This may be caused by unstable equipment installation, uneven liquid flow, and other reasons.

- To solve this problem, it is necessary to check the installation status of the equipment, ensure that it is placed horizontally, and adjust the equipment parameters such as flow rate, pressure, etc. according to the properties of the liquid.

(9) Difficulty in cleaning: After prolonged use, the emulsifier may need to be cleaned to maintain hygiene and performance. However, certain areas may be difficult to clean, such as dead corners, gaps, etc. Special measures or tools need to be taken to clean these areas.

(10) Insufficient pressure or inability to adjust:

- Reason: This may be caused by blockage in the middle and lower holes of the pilot valve, jamming or damage to the main or pilot valves of the unloading valve, or damage to the sealing ring of the thrust piston.

- The solution is to inspect and unblock, repair or replace these components.

(11) High pressure pulsation, insufficient flow or no flow:

- Reason: This may be caused by the air in the pump suction chamber not being cleaned thoroughly, the plunger sealing ring sucking in air, the suction pipe being too thin and bent, the suction valve spring breaking or the valve core being damaged, the suction valve plug not being tight, and the liquid tank suction filter being blocked.

- The solution is to loosen the air screw of the pump body, discharge the air, remove the drain valve, inject the liquid into the plunger chamber, replace the suction hose or eliminate dead corners, replace the spring or replace the valve core, tighten the suction valve plug, and clean the suction filter in the liquid tank.

2. How to purchase a good homogeneous emulsifying machine?

(1) Firstly, the type of material you need to handle is the core element that determines the type of the homogeneous emulsifying machine;

- For cream lotion in cosmetics industry, we recommend you to use the ZJR series homogeneous emulsifying machine underthe YeKeey brand;

- For daily chemical products such as hand sanitizers, toothpaste, shampoo, etc., we recommend you to use the SP series homogeneous emulsifying machine under the YeKeey brand;

- For industries such as egg yolk sauce, salad dressing, pet food, baby food, etc., we recommend you to use the MC series homogeneous emulsifying machine under the YeKeey brand;

- For ointment and gel in pharmaceutical industry, we recommend you to use the MC series homogeneous emulsifying machine under the YeKeey brand;

- For homogenizing emulsifiers used in laboratories or small-scale production, we recommend you to use the LR series homogeneous emulsifying machine under the YeKeey brand;

(2) Secondly, the capacity of the homogeneous emulsifying machine needs to be determined based on actual production needs; If you need to handle a large amount of materials, you can choose high-capacity equipment; If the production scale is small, small capacity equipment can be chosen.

(3) Then, it is also necessary to consider the performance parameters of the emulsifier: it is necessary to understand the power, speed, design of the working head, and material parameters of the emulsifier to meet the requirements of product processing.

(4) At the same time, it is necessary to consider the adjustability and flexibility of the emulsifier to meet the processing needs of different materials.

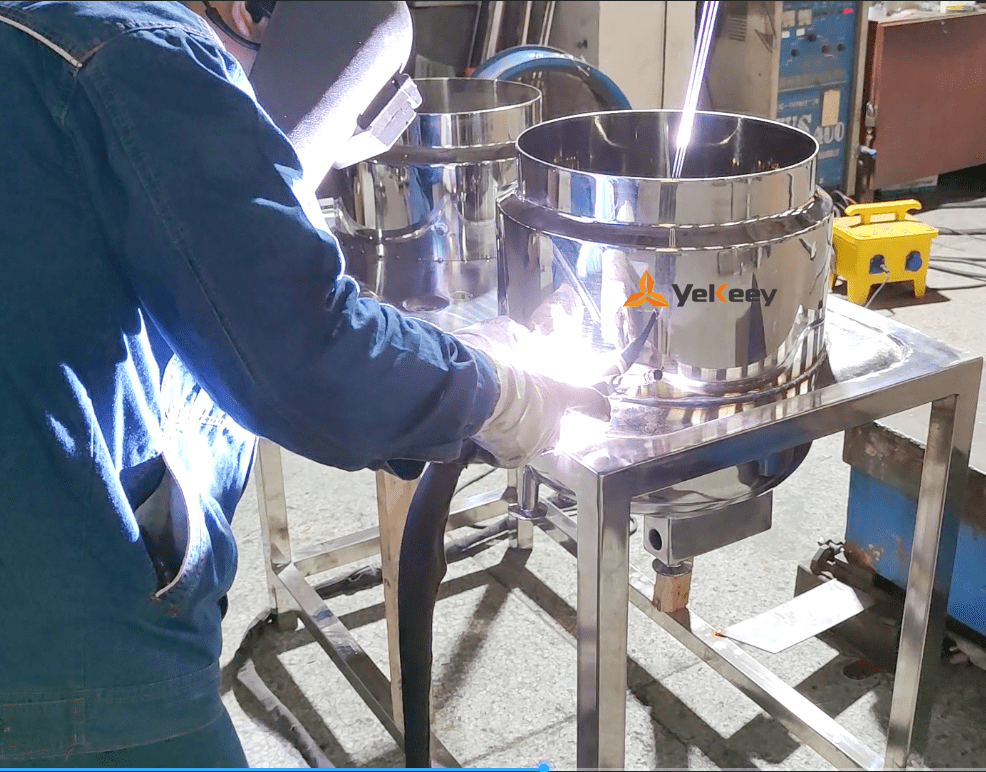

(5) Once again, the reliability of the homogeneous emulsifying machine: Choose a reliable brand and model of the emulsifier to ensure the stability and service life of the equipment. Hundreds of customer cases have proven that the service life of YeKeey emulsifying machines is over 20 years, and the failure rate is extremely low. The operation is simple, and customers who need to expand production line always will choose YeKeey to repurchase; In addition, as a factory, YeKeey can provide original replacement parts for vulnerable parts of YeKeey homogenizing emulsifiers, and can customize more suitable accessories or machines according to your production changes, which can greatly reduce equipment maintenance costs, reduce your downtime and production losses.

(6) Finally, the price of the homogeneous emulsifying machine: YeKeey always puts your interests first. On the premise of meeting your production needs and ensuring quality, YeKeey is willing to negotiate prices with you to ensure that you purchase the most suitable homogeneous emulsifying machine at the most competitive price.

You have a unique perspective to offer.

I am not sure where youre getting your info but good topic I needs to spend some time learning much more or understanding more Thanks for magnificent info I was looking for this information for my mission

C’est comme si vous lisiez dans mes pensées Vous semblez connaître beaucoup de choses sur ce sujet, comme si vous aviez écrit le livre ou quelque chose du genre Je pense que vous pourriez avoir besoin de quelques images pour faire passer le message, mais au lieu de cela, c’est un blog fantastique Une excellente lecture Je reviendrai certainement

I was suggested this web site by my cousin Im not sure whether this post is written by him as no one else know such detailed about my trouble You are incredible Thanks

Thank you for the auspicious writeup It in fact was a amusement account it Look advanced to more added agreeable from you By the way how could we communicate