Stock broth usually refers to boiled chicken broth, bone broth, and the like. In food seasonings, the broth is an auxiliary ingredient often used in cooking. It is put into other dishes for freshness and makes the dishes more flavorful.

In the morning in the 1970s, some developed countries such as Denmark and Sweden started to develop and produce bone broth. Domestic livestock and poultry bones are increasing year by year with the increase in total meat production, and many food companies have also begun to process and develop bone broth products.

What is the production machine for bone broth products?

With the advancement of industrialization, the innovation of technology and equipment, and the influence of fast-paced lifestyles, the form of making bone broth will become a thing of the past and making soup, broth, thick soup, etc. will become a thing of the past. Mainstream, which urges the food processing industry, food processing technology, biotechnology, and equipment manufacturing technology to develop rapidly.

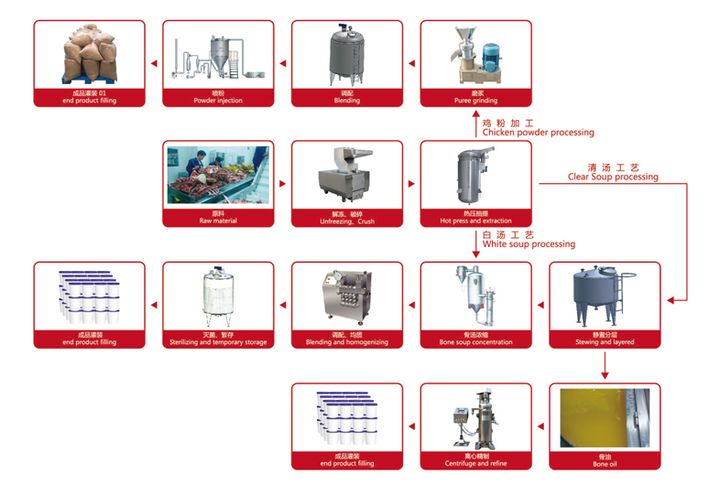

The industrialized production process of bone broth

Generally speaking, the process of industrial production of bone broth is: raw bone → crushing → washing → steaming → static → separation → concentrated liquid reconciliation → homogenization → sterilization → filling → cooling → storage.

Mature production technology is a reliable guarantee for the stability and uniformity of bone broth quality and flavor. In the current bone broth production enterprises, the process flow is not much different, but the product quality is significantly different. This has a lot to do with the company’s R&D investment and experience accumulation. The key processes of bone broth production are refining, reconciling, and homogenizing the key factors that determine product quality.

Let’s take a look at a high-shear homogenizer with a batch capacity of 1 ton in the delivery area of the YeKeey workshop. Homogenization is a technology often used in the production of food, chemical, biopharmaceutical, and other industries. Homogenization is to refine the material under the mechanical force of the high shear homogenizer so that the materials can be more uniformly mixed with each other so that the entire production system is more stable.

The high shear homogenizer ordered by the customer has been assembled and successfully passed the factory inspection. It is now ready to be packaged and shipped and sent to foreign companies engaged in the production of food condiments. This model LR-1000 high shear homogenizer will be used in the production of broth, and the batch output will reach 1,000 kg.

At the beginning of the order, through communication with the customer, we learned that the main products produced by the customer include hot pot dipping sauce, hot pot bottom sauce, Bobo chicken sauce, and other condiments. The high shear homogenizer purchased this time will be used for the production and preparation of pork bones, beef bones, fish meal, and chicken bone broth.

Homogeneous emulsification technology for processing broth products

The homogenizing emulsification technology of the high shear homogenizer refers to the process of making the dispersion in the suspension system micronized and homogenized. This treatment simultaneously reduces the size of the dispersion and improves the uniformity of the dispersion. Emulsification homogenization in food processing means that the material liquid is squeezed and the material is refined under the action of strong impact shear so that the materials can be more uniformly mixed with each other. YeKeey’s high shear homogenizer adopts German homogenizing emulsification technology, which can fully and uniformly homogenize and emulsify, ensuring the product uniformity and stability of bone broth products.

Homogenizers are often used in the production process of food and daily chemical industries. The high shear mixer developed by YeKeey is more widely used because of its good homogenization effect, low price, diversified installation methods, convenient installation, and low maintenance cost. Application.