YeKeey Vacuum Emulsifying Mixer is suitable for mixing production in cosmetics, pharmaceutical, and food industries. It is a high-end dispersing, stirring, and homogenizing emulsifying equipment. For some of the process is difficult to synthesize the product, often can also bring customers a significant surprise seasonings effect! Recently, the newly developed sixth-generation laboratory vacuum homogenizing emulsifier was successfully tested for lithium battery customers from the new material industry. The customers were surprised and satisfied with the homogenizing and dispersing effect of the finished products.

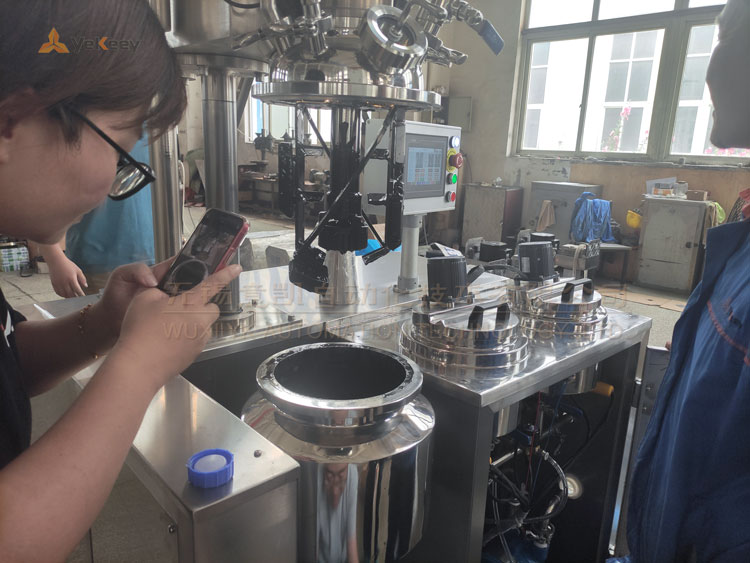

Test scene of the sixth-generation laboratory dispersion homogenizing emulsifier

As the mainstream solution for automotive power batteries in recent years, there are many preparation processes for lithium batteries. There are various solutions for the equipment industry used in each process. At the same time, with the development of new solutions are entering.

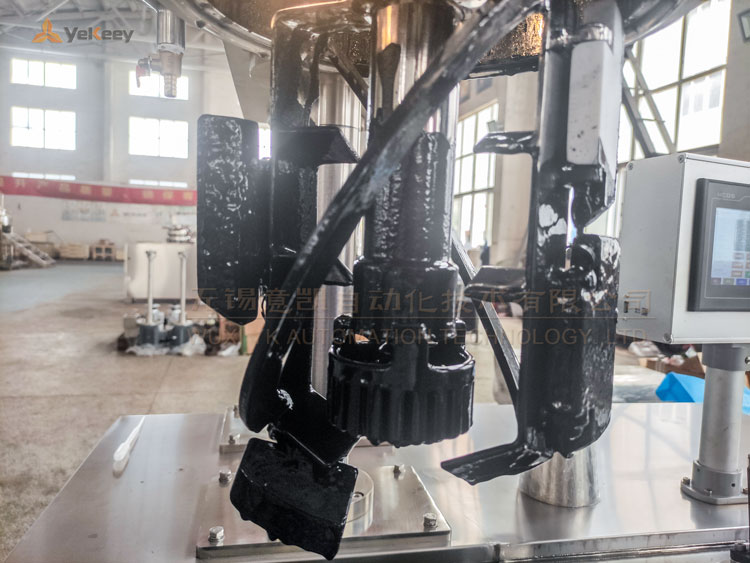

It is understood that the raw material of the test machine is lithium battery slurry, the cost of the material is very high, the quality of the slurry dispersion quality directly affects the quality of the production and the performance of the product. Therefore, mixing and dispersing are very important in the production of the customer’s products, and the lithium battery slurry-making machine is the key. The customer had tried other machines before, but the effect was not satisfactory. The raw materials of the test machine are mainly powder and liquid binder liquid and liquid, liquid and solid material between the mutual mixing, dissolution, dispersion, and a series of technological processes.

The sixth-generation laboratory vacuum emulsifying machine is mainly composed of emulsifying tank, oil tank, water tank, vacuum system, hydraulic system, electrical control, and other parts. Inheriting the leading technology and scientific design of the fifth-generation laboratory emulsifier, with its high efficiency, scientific nature, and stability, the sixth-generation laboratory emulsifier has the following advantages. It has the following characteristics: people-oriented design, simple operation, compact structure, stable performance, good homogenizing effect, high production efficiency, convenient cleaning and maintenance, and a high degree of automatic control. Adopt 316L stainless steel material, PLC automatic control system, new design, high-tech experience!

After the material brought by the customer is fully mixed and stirred in the emulsifying tank, the pot cover is slowly raised under the control of PLC. The expert and professional customer technical personnel through the observation of the fluidity of the material in the pot and the homogeneous mixing box and some physical properties, summed up into a word and blurt out: “good”! Later, we learned that the customer had failed many times, but this time it was successfully prepared through the sixth generation laboratory vacuum emulsifying machine of YeKeey! The effect is unexpectedly good! The battery paste out of the pot flows out from the bottom valve of the pot. The customer is ready to bring the finished product back to the headquarters of the company to report to the leader! The customer expressed to us the intention of purchasing equipment, and the follow-up cooperation is in progress happily!

Functional application of laboratory emulsifier

Homogenization, emulsification, depolymerization, dispersion: vaccine, fat milk, agricultural drugs, yogurt, textile additives, suspension, fruit juice, cell crushing, oil-water emulsification, coal slurry, cosmetics, asphalt, pigment, essence, tissue homogenization.