Stainless steel mixing tanks are also called the batching tank. It is a piece of essential equipment in the batching industry. It is suitable for mixing and stirring different materials. It is suitable for the fields of food, dairy products, fruit juice beverages, pharmaceutical chemicals, and biological engineering. It integrates heating, stirring, Homogenization, temperature control, cooling, and other functions are integrated, and it is a powerful assistant in the mixing and batching industry.

The stainless steel mixing tank can be equipped with heating and cooling devices according to the process requirements of the user’s product to meet different process and production needs. When it comes to the functions of heating, cooling, and heat preservation, the mixing tank can be divided into single-layer, double-layer, and three-layer structures. Tanks with different layers will have different functions. What are the characteristics of tanks with specific single-layer, double-layer, and three-layer structures?

Generally speaking, single-layer stainless steel tanks can be used for storing materials. In the case of heating, cooling, and other functions, choose double-layer tanks. If heating, cooling, and heat preservation are required, it is recommended to choose a three-layer structure jacket insulation and stirring can.

Application of stainless steel mixing tanks with different layers:

Single-layer stainless steel storage tanks:

Single-layer stainless steel storage tanks are also called transfer tanks. The storage tank wall has only a single layer. It is usually only used as a container for storage, stirring, mixing, and reaction. If heating or cooling is required, only internal coil heating or Cool, or directly insert an electric heating tube into the mixing tank for heating.

Double-layer stainless steel mixing tank:

A double-layer stainless steel tank refers to a jacketed tank, also called a jacketed mixing tank. The jacket layer can be used for heating, cooling, and heat preservation. The heating methods include heat transfer oil circulation heating, water circulation, and steam heating. , Electric heating, etc. The double-layer stainless steel mixing tank transfers heat to the material through the medium in the jacket. The heat transfer speed is fast, safe, and hygienic. However, the double-layer stainless steel mixing tank needs to be careful to prevent scalds when heating the material, and the heat of the tank is easy to volatilize.

Three-layer stainless steel mixing tank:

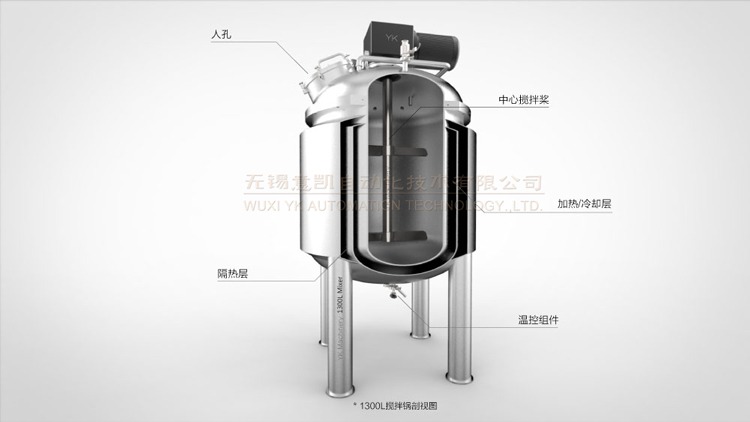

The three-layer stainless steel mixing tank is a double-layer stainless steel mixing tank with an insulation layer, the middle layer is used for heating or cooling, and the outer layer is used for insulation.

Regarding the price of single-layer, double-layer, and three-layer mixing tanks:

In terms of price, depending on the configuration, the price of stainless steel mixing tanks with different layers is different. Generally speaking, the price of double-layer stainless steel mixing tanks of the same specification is higher than that of a single-layer, and the price of a three-layer is higher than that of a double-layer. Therefore, when choosing a stainless steel mixing tank, customize the number of layers of the mixing tank according to the actual situation, and choose the stainless steel mixing tank that suits you.

Stainless steel mixing tanks product by Yekeey

Wuxi Yekeey produces a variety of stainless steel stirring tanks of different specifications, including 50 to 10 tons of different specifications, using high-quality SUS304, SUS316L stainless steel materials, equipped with high-speed agitators, low-speed agitators, wall scraping agitators, etc. Customized by Yekeey the mixing tank can be equipped with different functional modules such as heating, cooling, vacuum, pressurization, etc. We accept non-standard customization, welcome to inquire!

Thanks for explaining that mixing tanks are often used in the food and pharmaceutical industry since they’re used to mix and stir different materials. I imagine if you work for a beverage manufacturing company, it would be wise to get your water tank mixing unit from a trusted industrial equipment supplier. I’ll be sure to keep this in mind if I ever think of investing in the food and beverage industry in the future.