Emulsification homogenizers refer to the equipment with emulsifying and homogenizing functions. In view of the non-standard characteristics of emulsification homogenizers, there are many styles of emulsifying homogenizer machines on the market. The configuration and core technology are all different, and the levels vary. Today, let’s take a look at the difference between the emulsification tank and the pipeline emulsification pump from the structure.

The Relationship Between these Two Emulsification Homogenizers

First of all, it is simple and clear to understand the relationship between these two emulsification homogenizers. In terms of substitution, the emulsification tank can replace the pipeline emulsifier to a greater extent. In the case where an emulsification tank is required, the pipeline emulsifier basically cannot replace the emulsification tank. Why?

Pipeline Emulsifier Pump

The pipeline emulsifier pump is generally a structure in which a multi-stage homogenizer is installed in a pipeline. In terms of improving the emulsification effect, it can achieve a better emulsification effect by increasing the number of homogenizer stages or the homogenization speed. For industries such as pharmaceuticals and cosmetics with complex technological processes, they have certain requirements for the homogenization speed, but they cannot be too high. In-line emulsifiers with a single function and easy to cause demulsification are not suitable for producing high-quality products. Therefore, the pipeline emulsifier is suitable for the production of products that require a single emulsification treatment, the emulsion is stable and not easy to break, and requires continuous production.

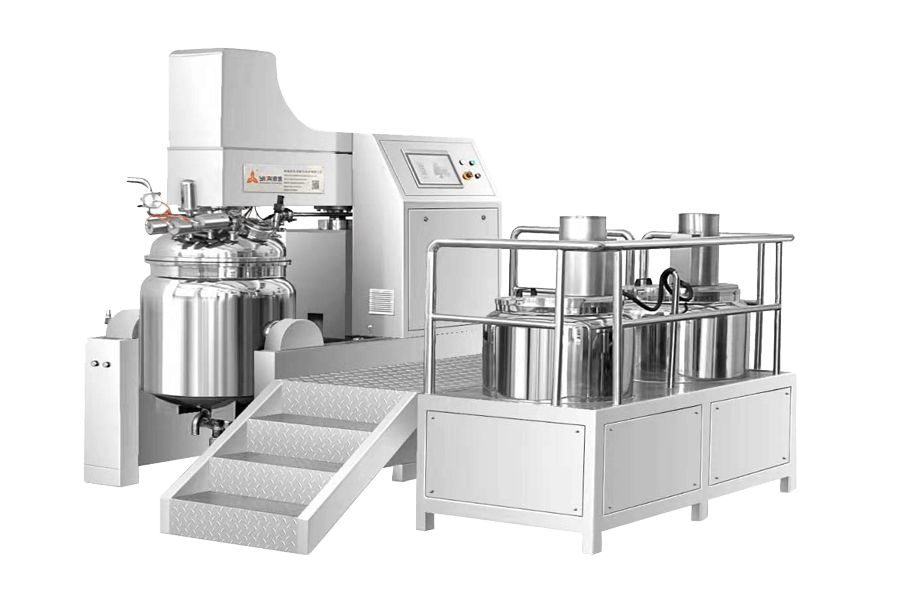

Emulsification Tank

The emulsification tank refers to an emulsifier with a stirring tank. In terms of improving the emulsification effect, the emulsification mixing tank can add many functional modules to achieve a better emulsification effect. In addition to the homogeneous emulsification treatment, the mixing tank of the emulsification machine can be equipped with heating and cooling functions, vacuum suction, defoaming functions, diversified homogeneous stirring combinations, and various working head styles. The above customized modular function system allows the emulsification mixing tank to better fit the customer’s production process, making your production more intelligent and controllable, and laying a solid hardware foundation for the production of high-quality products.

Conclusion

To sum up, the pipeline emulsifier pump and the emulsification tank are both types of emulsifiers, and their existence is reasonable. If the process requirements are simple homogeneous emulsification and continuous production, you can choose a pipeline emulsifier, which is more cost-effective. If your process requirements are more complex, such as: for the uniformity and uniformity of emulsification and dispersion; functional processing such as heating and vacuum is required; and the requirements for hygiene are relatively high; it can also be produced in batches, the emulsification mixing tank is suitable for you choose.

Tips for the Selection of Emulsification Equipment:

- Clarify the effect and purpose of using the equipment

- Understand and master the properties of the research materials in detail (including physical and chemical properties)

- Specification selection according to output

- Determine the operating parameters and structural design of the equipment again

The above is the difference between the emulsification tank and the pipeline emulsifier. How to choose the model? For related introductions, I hope that they can help you in the understanding and selection of these two emulsifiers. If there are still problems in the follow-up, please contact YeKeey for consultation.