In the domestic cosmetics machinery market, vacuum emulsifier as a sought-after cosmetic machine is often accompanied by embarrassment. Quality issues are often the main cause of embarrassment. When many customers contact YK, they often complain about the quality problems of the previously purchased vacuum emulsifier equipment, resulting in a series of troubles and losses. These customers, some of the channels they purchased before are emulsifier manufacturers, some are trade brokers, some are bought second-hand.As the saying goes, water is active and the tree has roots. If you are not looking for the cause of the quality problems of the emulsifier equipment, the upstream factory as the leader of production research and development, it is certainly difficult to blame. On the one hand, the bad brand madness has played a certain role in promoting. On the other hand, it doesn’t matter if some factories don’t stick to their own bottom line.

Vacuum Emulsifier Quality Assurance Four Elements

In fact,YK did a lot in ensuring the quality of the vacuum emulsifier. It also promotes the transformation and transformation of the emulsifier industry, step by step towards intelligent quality!

1.Strict screening of raw material suppliers

Pursue reliable raw materials and components. 85% of the parts are imported quality products. Supplier training sessions are held on a regular basis so that each supplied component can be more in line with the preparation requirements of the emulsifier. This provides a solid foundation for the manufacture of high quality emulsifiers.

2.Accumulate strong research and development strength

In fact, Wuxi YK has a professional emulsifier research and development team. We have a group of professional R&D and technical personnel with high academic qualifications and rich experience in the industry. At the same time, the company also cooperates with a number of universities in technology, talents, industry, research and research. In terms of talent absorption and design techniques and concepts, we are constantly aligning with cutting-edge new technologies to ensure the vitality of R&D innovation. For the company’s products are also constantly updated, upgrade optimization! This kind of research and development strength and product quality have enabled YK products to obtain multiple product certifications. The products are not only sold well in China, but also exported to more than 100 regions abroad.

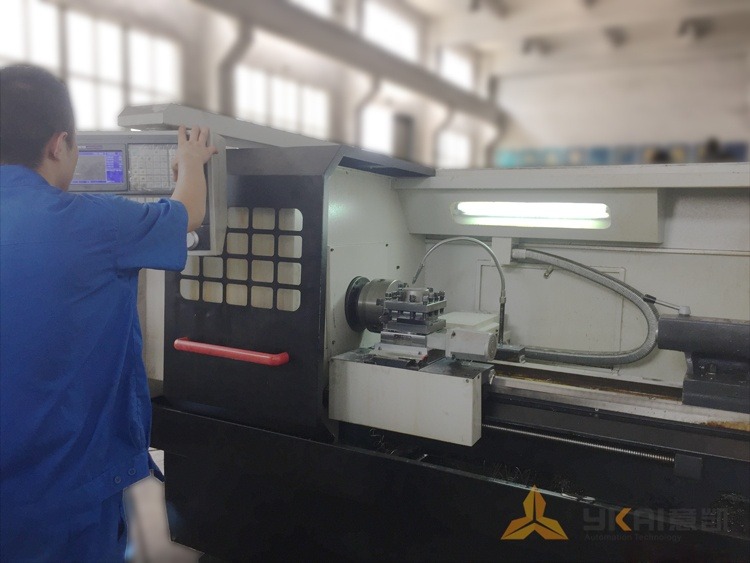

3.The leading production equipment helps Yikai to ensure the quality of the emulsifier is guaranteed.

YK has a production area of 20,000 square meters, a modern equipment manufacturing plant, and uses advanced production equipment. Efforts have been made to improve the quality of homogeneous emulsification equipment products, increase production efficiency, and digest the rapidly increasing order volume. In such a high standard production environment, of course, a better quality vacuum emulsifier equipment can be produced.

4.Not only that, but Yikai also strictly enforces standards.

The production process of the emulsifier, each production process is refined, the division of labor is clear, and the responsibility is in place. Through standardized work processes and perfect enterprise hardware facilities, YK can achieve high quality requirements.

It is precisely in these four aspects that strict requirements, Yikai vacuum emulsifier equipment, is really worthy of the “high quality” word.