Recently, there was a company working on essence and flavor, consulted us on the emulsifying machine of essence, including the glue dissolving tank, mixing agitation tank, initial emulsifier, and high shear homogenizer for the simple reason that the old production equipment of essence has produced uneven grain size of emulsified essence. As a result, the client had a very strong desire to replace the old generation equipment with new ones. As the client got to know that YeKeey has a complete set of the emulsification equipment of essence, so they consulted about the relevant equipment.

According to the description of the customer, their equipment for the production of essence and flavor is divided into several processes, which requires going through several pieces of equipment, and the raw materials also need to be transferred multiple times. The work processes are complex, and the workload of the operators is too much, which consumes a large amount of time and energy. What the customer loves most is the working effect and hygiene of the equipment that are difficult to guarantee. There must be some essence production equipment producing the products has been unqualified under the analysis of testing and sampling using the microscope, centrifugal machine, viscometer, and other auxiliary equipment. One of the main reasons for the key equipment affecting particle size is the homogenizer. Due to the long time of use, wear of homogenizer head, and inadequate cleaning and maintenance of customers, it makes the homogenization nonuniform for such reasons, and the particle observation of sampling is not qualified. It is difficult to upgrade the products on the grounds of high labor costs, complicated process, es and unqualified products, so it is imperative to upgrade the equipment.

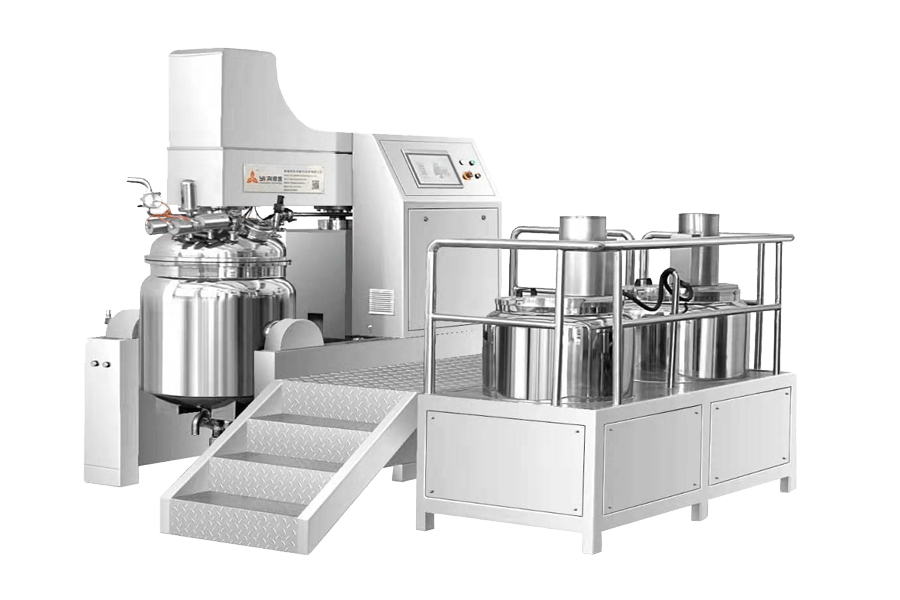

This customer’s equipment is the traditional old one. Nowadays, the main production equipment for making essence and flavor is generally using an integrated food equipment with multi-functions. Of which, vacuum homogeneous emulsifier is more popular because it has the function of integration: the pretreatment tank and the main emulsifying tank are connected to the platform through the pipeline (150L or more), the feeding and output of raw materials can be sucked and discharged through the vacuum pipeline, which greatly saves manpower and at the same time greatly reduces the chance of raw materials being polluted by the outside world. The integration of the equipment makes it more space-saving, better layout of the production line, more convenient to operate, and safer in use. Meanwhile, the process equipment can be well.

More importantly, vacuum emulsifying machine equipment of YeKeey adopts the first-rate homogeneous technology derived from Germany, which can efficiently process materials at the shortest time through shearing and thinning on a micron-grade basis, or even on a nanometer-grade basis. It is a good way to guarantee the emulsification of emulsified essence up to standard, depending on a scientific combination mode of mixing and homogenizing, and let the mixture of raw materials is more uniform, delicate, stable. YeKeey is always in a position to help you if you want to know more about our emulsifiers.