Ice cream is a frozen dairy product whose physical structure is a complex physical and chemical system. Air bubbles are dispersed in a continuous liquid with ice crystals. This liquid contains fat particles, milk proteins, insoluble salts, lactose crystals, gums. Body stabilizers and sucrose, lactose, soluble salts, such a three-phase system consisting of the gas phase, liquid phase, and solid phase, can be regarded as a partially frozen foam containing 40%-50% air by volume.

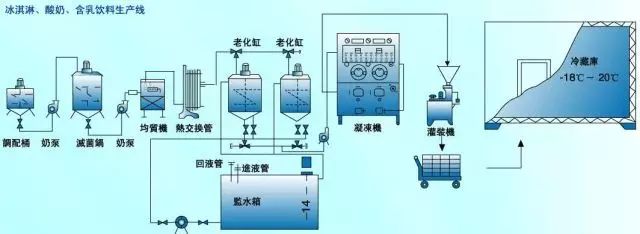

Ice Cream Production Process

The production process of ice cream mainly includes several processes such as inspection of raw materials, mixing and sterilization of ingredients, homogenization, cooling, aging, freezing, forming and filling, quick freezing, hardening, and storage. These processes must be completed in accordance with certain technical conditions, otherwise, high-quality products cannot be produced. We know that in the production and storage process of ice cream, the vacuum emulsifier mixing equipment in the homogenization of ingredients plays a vital role.

In the traditional ice cream production process, due to the single technology, the homogenization of ingredients is divided into several links. This traditional solution wastes a lot of equipment cost, manpower, and production workshop space, and the multi-link transfer of raw materials also greatly increases the chance of materials being polluted by the outside world, and the hygiene level is low.

Ice Cream Ingredient Mixing Equipment

The picture above is an overview of the on-site installation and commissioning of the homogenizer emulsifier equipment for the ingredient link ordered by an ice cream manufacturer in Shenyang. This ice cream ingredient mixing equipment is an advanced multi-functional integrated ingredient homogenizing emulsifier equipment. It has changed the traditional complicated multi-link form, and one machine can complete the processing of batching, premixing, homogeneous emulsification, jacket sterilization, and filtration. And the material is transported through the pipeline, which is hygienic and clean and meets the requirements of food production.

The equipment model of this vacuum homogeneous emulsifier is SPC-650, and the processing capacity is 520 kg/batch. The steam heating method is according to customer requirements.

Conclusion

From feeding, pre-mixing, heating, process control, homogeneous emulsification stirring, cooling, to discharging and cleaning, it can be directly completed on the vacuum emulsification mixer unit to realize automatic vacuum feeding, discharging, speed, temperature, and time control. Reduce the batching process and improve production efficiency. At the same time, it also automates and simplifies the entire liquid mixing and ingredients process, which greatly saves manpower, reduces material waste, and improves the quality of ice cream products.