The automatic tube filling and sealing machine is an automated equipment used to fill liquids, pastes, colloids, and other substances into the tube and perform sealing operations. The following is a detailed introduction to the definition, application, characteristics, advantages and disadvantages, as well as procurement methods of the automatic tube filling and sealing machine:

-

Definition

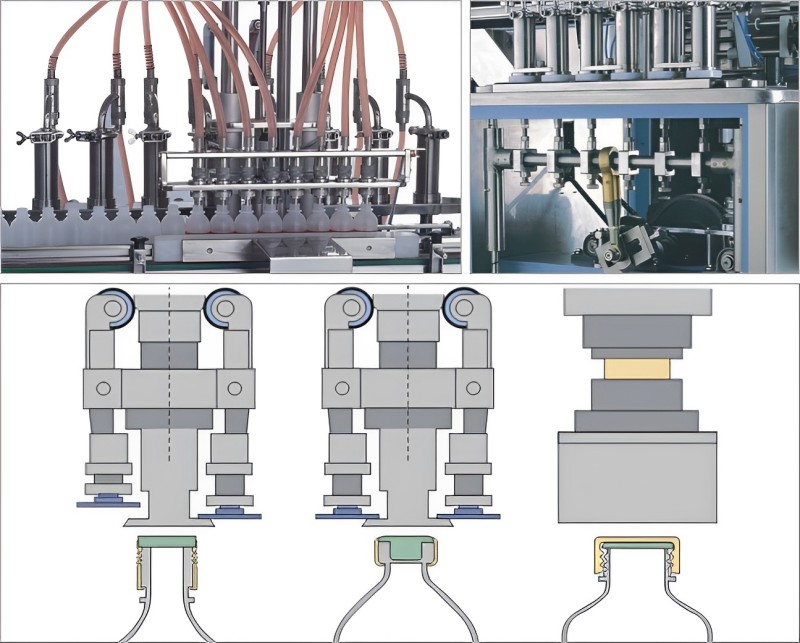

The fully automatic tube filling and sealing machine is a device that can automatically complete filling and sealing operations. It adopts advanced mechanical components and control systems, which can efficiently and accurately complete the filling and sealing process of hoses.

-

Application

The fully automatic tube filling and sealing machine is widely used in industries such as cosmetics, food, and medicine. It is suitable for filling and sealing various liquids, pastes, colloids and other substances, and can meet the needs of different industries for product filling.

-

Features

(1) High degree of automation: The fully automatic tube filling and sealing machine adopts advanced mechanical components and control systems, which can achieve fully automated operation, improve production efficiency and product quality.

(2) High filling accuracy: The fully automatic tube filling and sealing machine adopts a high-precision measuring and control system to ensure the accurate amount of liquid in each hose and stable and consistent sealing effect.

(3) Easy and convenient operation: The fully automatic tube filling and sealing machine generally adopts touch screen operation, which is simple and convenient to operate, and easy to learn and master.

(4) Strong adaptability: The fully automatic tube filling and sealing machine can adapt to different specifications and types of hoses and liquids, with great flexibility to meet different production needs.

(5) Efficient and energy-saving: The fully automatic tube filling and sealing machine adopts advanced energy-saving technology and equipment, such as high-efficiency motors and low energy consumption control systems, to reduce energy consumption and operating costs.

-

Advantages

The fully automatic tube filling and sealing machine has the characteristics of high speed and high efficiency, which can quickly complete the filling and sealing process of tubes, improving production efficiency; At the same time, it can ensure that the filling and sealing effects of each hose are stable and consistent, avoiding potential quality fluctuations caused by human operation. In addition, it can also save labor costs, reduce labor intensity, and improve production efficiency.

-

Disadvantages

The initial investment of the fully automatic tube filling and sealing machine is relatively large, requiring certain technical maintenance and upkeep. In addition, for certain special liquids or special specifications of hoses, it may be necessary to customize equipment or adjust equipment parameters.

When purchasing a fully automatic tube filling and sealing machine, the following factors need to be considered:

(1) Production demand: Select appropriate equipment specifications and models based on actual production needs to ensure they can meet production needs and improve production efficiency.

(2) Product quality: Select equipment that can ensure product quality, ensure that the amount of liquid in each hose is accurate and in compliance with relevant quality standards and regulations.

(3) After sales service: Choose a manufacturer with good after-sales service to receive timely maintenance and repair during use, ensuring the normal operation and service life of the equipment.

(4) Price: On the premise of meeting production needs and quality, choose equipment with reasonable prices and consider the long-term investment return rate of the equipment.

(5) Technical support: Select manufacturers who provide technical support in order to receive timely technical support and solutions during use, and solve any problems that may arise during equipment operation.

(6) Case and reputation: Understand the manufacturer’s case and reputation, choose a manufacturer with successful cases and good reputation, and ensure the quality and service level of the equipment.

Welcome to inquiry!

I do not even know how I ended up here but I thought this post was great I do not know who you are but certainly youre going to a famous blogger if you are not already Cheers

Thanks I have recently been looking for info about this subject for a while and yours is the greatest I have discovered so far However what in regards to the bottom line Are you certain in regards to the supply

Wow superb blog layout How long have you been blogging for you make blogging look easy The overall look of your site is magnificent as well as the content

you are in reality a just right webmaster The site loading velocity is incredible It seems that you are doing any unique trick In addition The contents are masterwork you have performed a wonderful task on this topic

Great post! Very informative and well-written. Looking forward to more content from this blog!Thank you