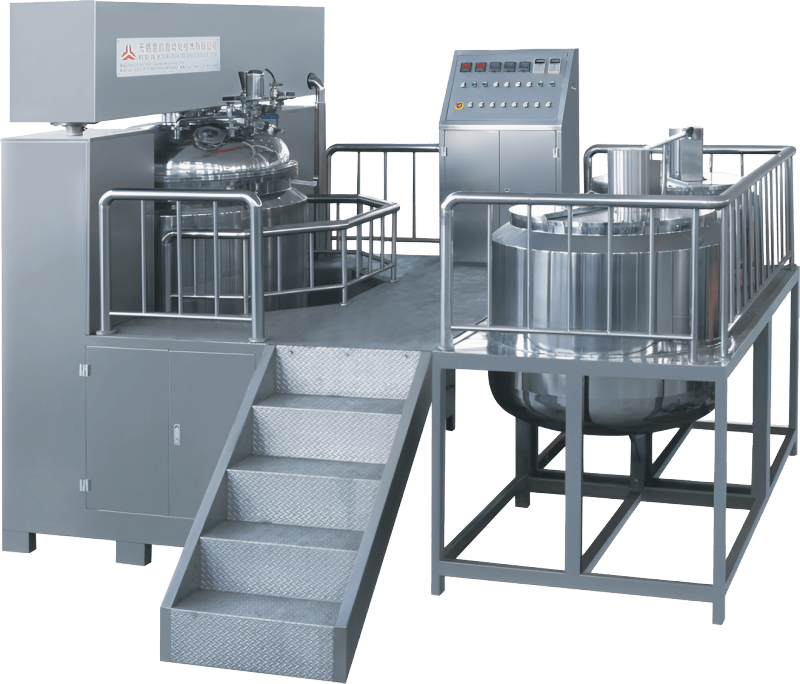

The shampoo making machine is the homogenizing emulsify mixer. The shampoo making equipment, namely the homogenizing emulsify mixer, plays the most crucial role in the entire shampoo making process. A suitable emulsify mixer can not only improve the quality of shampoo, but also shorten production time, bringing you higher profits.

The making steps for shampoo are as follows:

- Purchase of shampoo making machines

- Design formula: Determine the raw material composition and ratio of shampoo.The main formula of shampoo is surfactant (such as sodium dodecyl sulfate), conditioner (such as serine), thickener (such as hydroxyethyl cellulose), functional auxiliary, essence/preservative/pigment, other additives, etc.

- Material preparation

- Shampoo making machine: Put the raw materials into the homogenizing emulsify mixer according to their ratio and order for heating, stirring, and mixing.

- Adjust pH value: According to the shampoo formula, use acid or alkali to adjust the pH value of shampoo to ensure it is within the required range.

- Adding additives: Gradually add moisturizers, conditioners, preservatives, spices, and other additives to the mixture as needed. The function of these additives is to provide additional functionality and fragrance.

- Mixing and stirring: Continue mixing and stirring in the shampoo making machine – the homogenizing emulsify mixer, ensuring that all ingredients are evenly distributed and there are no obvious particles or clumps.

- Inspection and adjustment: Conduct quality inspection on shampoo, including appearance, odor, consistency, pH value, etc. Make minor adjustments as needed to ensure that the product meets the standards.

- Packaging: Place shampoo in a suitable container, such as a bottle or tube; And add labels on the shampoo packaging container. Automated packaging equipment can be used to complete this step.

- Quality control: Conduct quality control testing on the final product to ensure compliance with relevant regulations and standards.

This is just a general overview, and the specific steps and processes may vary due to the different categories of shampoo products.

It should be noted that, in the entire shampoo making process, you may encounter the following issues:

- Insoluble particles or clumps appear in the product

- The viscosity of the system is too high or too low

- The product exhibits layering phenomenon

- Jelly phenomenon occurs in the product

- Product stability issues

So how do we solve these problems?

It is not difficult to see that these problems are all caused by the poor performance of the shampoo making machine. Which type of the homogenizing emulsify mixer does it work best to choose and use?

Yekeey homogenizing emulsify mixer machine is undoubtedly the best choice. The reason is Yekeey homogenizing emulsify mixer machine can not only match you with the best and cheapest shampoo making machines based on your materials, viscosity, discharge speed, etc., but also customize vacuum, heating, explosion-proof and other functions according to your needs to minimize your costs and maximize your profits.