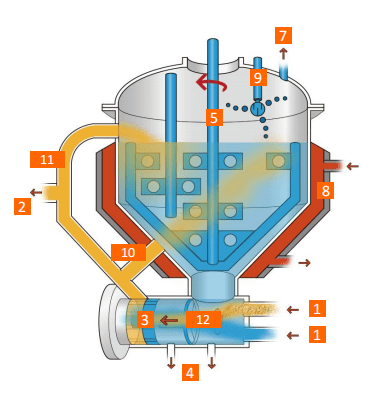

Production process of Mayonnaise Machine

1. Egg & Oil infeed

2. Product discharge

3. Homogenizer

4. Residue discharge

5. Scraper agitator

6.Center rotating agitator

7. Vacuum system

8. Heating & Cooling

9. CIP

10. Internal loop

11. External loop

12. Premix

Considering factor

- The viscosity of the material

- The method of mixing

- The type of mixer to be used

- The speed at which it should be operated

- The number of agitators

- The number of blades

Production steps

- At first, the egg isdispersed into the water as liquid or powder form .

- Secondly, the oil is added in the next stage.

- Mixing is continuous while the oil is added until the mixture reaches a high viscosity.

- During the cooling process, the temperature should be below 5 ° C.

- Vinegar and the oil are further added slowly.

Advantages

- More efficient

- Unique and efficient mixing and recycling homogenization system;

- Powder like material can be inhaled, dust-free, and quickly dispersed;

- Higher viscosity: Up to 100000mpas maximum viscosity

- Faster discharge: The homogenization system comes with a pump, which can shorten the discharge time

- Shorter production time: Compared to other series of emulsifiers, it can reduce production time by 60%

- Better seal: Adopting sanitary double-sided mechanical seals

- Easier to operate: The operating interface is more reasonable and ergonomically designed

- Easier to clean: with CIP function

- The minimum production capacity can reach 20% of the full capacity

- Support Customization: Sterile emulsification system

Technical Data of Mayonnaise Making Machine Mixers

|

Type |

MC-H-15 | MC-H-150 | MC-H-350 | MC-H-650 | MC-H-1300 | MC-H-2400 |

| Total volume(L) | 15 | 150 | 350 | 650 | 1300 |

2400 |

|

Useful volume(L) |

3-12 | 25-120 | 60-300 | 70-500 | 200-1100 | 220-2000 |

| Scraper agitator power(kW) | 0.37 | 1.5 | 2.2 | 2.2 | 4 |

5.5 |

|

Homogenizer power(kW) |

4 | 11 | 18.5 | 18.5 | 37 | 37 |

| Circumferential speed(m/s) |

3-24 | 5-22 | 5-25 | 5-25 | 6-28 |

6-28 |

|

Vacuum pump(kW) |

0.75 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 |

|

Dimension/mm |

||||||

|

Height(dosed cover) |

1650 | 2100 | 2400 | 2700 | 3100 | 3700 |

| Height(open cover) | 1600 | 2250 | 2600 | 2900 |

|

|

|

Width |

900 | 1500 | 1800 | 1900 | 2100 | 2300 |

| Depth | 1400 | 1600 | 2000 | 2300 | 3000 |

3100 |