Vacuum Emulsifying Mixer

Cosmetics industry

- Creams

- Lotions

- Sun protection products

- Decorative cosmetics

- Body-care products

- Collagen suspensions…

Food industry

- Mayonnaise

- Ketchup

- Salad sauce

- Baby food

- Pet food

- Liquid spices…

Daily Necessities

- Hand washing paste

- Liquid soap

- Tooth paste

- Shaving cream

- Shampoo

- Shower gel

- Hair care products

- Bubble baths …

Pharmaceutical

- Ointments

- Gels

- Eye ointment

- Mixtures and similar

- Lotions (W/O resp. O/W)

- Paraffin emulsions, Lipid emulsions…

Product Description of Vacuum Emulsifying Mixer

In the manufacturing process of above, the problem you might facing:

- One is: The dispersed phase particle size and mixing the air mixed with products, grain size is too large a everywhere emulsion instability, lack luster

- The other is: Products into the air will make the products bubble, bacterial contamination, easy oxidation and the appearance is not smooth.

The solution——ZJR series vacuum homogeneous

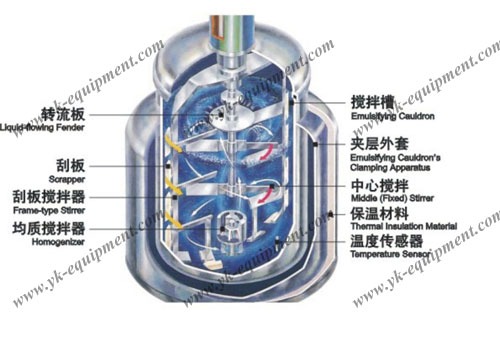

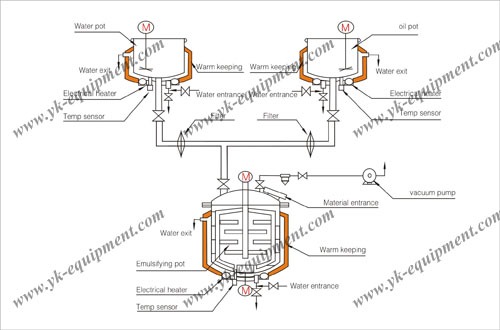

- By mixing with high-quality mixing blades, scraping the walls, and stirring in the center, they complement each other to form the best mixing method and achieve a perfect mixing product.

- The color and vacuum pumping method ensure that there are no bubbles during the mixing process at the production outlet, which can produce high-quality products with luster, delicacy, and good ductility.

Advantages of Vacuum Emulsifying Mixer

1. Better emulsification result

- Lotion is more stable, and the droplet size is less than 5um

2. Suitable for high viscosity materials

- up to 80000mpas in viscosity

3. High precision

- PID temperature control, rapid heating

4. Safety

- There is an insulation layer outside the heating inter-layer to prevent operators from getting burned

5. Convenience

- The structure is easy to clean and maintain

6. Support customized functions

- vacuum/sterile/explosion-proof/voltage

Product parameters of Vacuum Emulsifying Mixer

| Name | ZJR-1000 | ZJR-1300 | |

| Emulsifying Pot | Design Volume (L) | 1000 | 1300 |

| Capacity (L) | 800 | 1000 | |

| Scraper Stirring Power (KW) | 4 | 4 | |

| Scraper Stirring Speed (rpm) | 0-45 | 0-45 | |

| Homogenizer Power (KW) | 15 | 18.5 | |

| Electrical Heating Power (KW) | 24 | 24 | |

| Homogenizer Speed (rpm) | 2800 | 2800 | |

| Water Pot | Design Volume (L) | 650 | 800 |

| Capacity (L) | 500 | 650 | |

| Power (KW) | 1.5 | 1.5 | |

| Speed (rpm) | 960 | 960 | |

| Electrical Heating Power (KW) | 18 | 18 | |

| Oil Pot | Design Volume (L) | 500 | 650 |

| Capacity (L) | 400 | 500 | |

| Power (KW) | 1.5 | 1.5 | |

| Speed (rpm) | 960 | 960 | |

| Electrical Heating Power (KW) | 18 | 18 |

| Name | ZJR-1000L | ZJR-1300L | ||||

| Length | Width | Height | Length | Width | Height | |

| Emulsifying Pot Rack | 2700 | 1350 | 3230-4700 | 2800 | 1500 | 2960-4560 |

| Water and Oil Pot Rack | 2700 | 1250 | 2150 | 2800 | 1320 | 2200 |

| Table | 2700 | 850 | 2400 | 850 | ||

| Overall | 3750 | 3620 | 3230-4700 | 4900 | 3320 | 2960-4560 |

| Name | ZJR-2000 | |

| Emulsifying Pot | Design Volume (L) | 2000 |

| Capacity (L) | 1600 | |

| Scraper Stirring Power (KW) | 7.5 | |

| Scraper Stirring Speed (rpm) | 0-45 | |

| Homogenizer Power (KW) | 30 | |

| Electrical Heating Power (KW) | 30 | |

| Homogenizer Speed (rpm) | 2800 | |

| Water Pot | Design Volume (L) | 1200 |

| Capacity (L) | 960 | |

| Power (KW) | 2.2 | |

| Speed (rpm) | 960 | |

| Electrical Heating Power (KW) | 24 | |

| Oil Pot | Design Volume (L) | 950 |

| Capacity (L) | 760 | |

| Power (KW) | 2.2 | |

| Speed (rpm) | 960 | |

| Electrical Heating Power (KW) | 24 |

| Name | ZJR-2000 | |||

| Length | Width | Height | ||

| Emulsifying Pot Rack | 3250 | 1250 | 3300-4800 | |

| Water and Oil Pot Rack | 3250 | 1600 | 2225 | |

| Table | 3250 | 1500 | ||

| Overall | 4800 | 4400 | 3300-4800 | |